How To Flush Water Out Of Hydraulic System

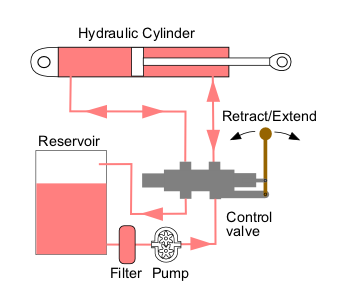

How to flush water out of hydraulic system. Reply to Quote Reply Add Photo _____ How to Flush Tractor Hydraulic Fluid. The goal here is to move the contaminated water out of the system quickly while minimizing the risk that it will be consumed. Store your tractor inside and replace rubber seals when they start to show wear.

Get a Barrel Heater from someone like WW Grainger. Bring the oil to operating temperature and shut the system down. Also if you leave a pail of hydraulic oil out in the rain or snow you will have moisture enter the container and it is very hard to detect when you are pouring it into the tank until the deed is done.

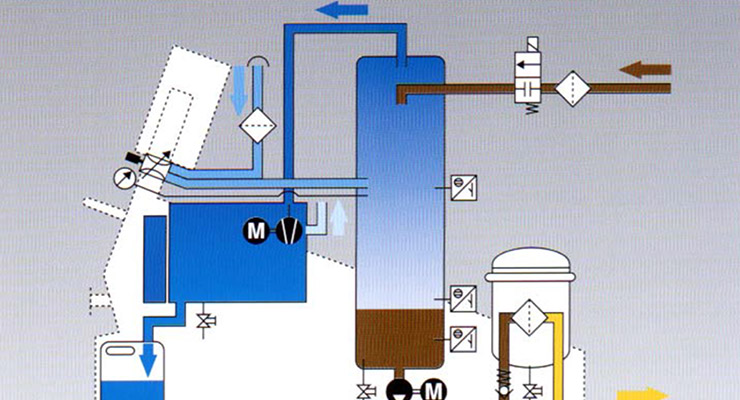

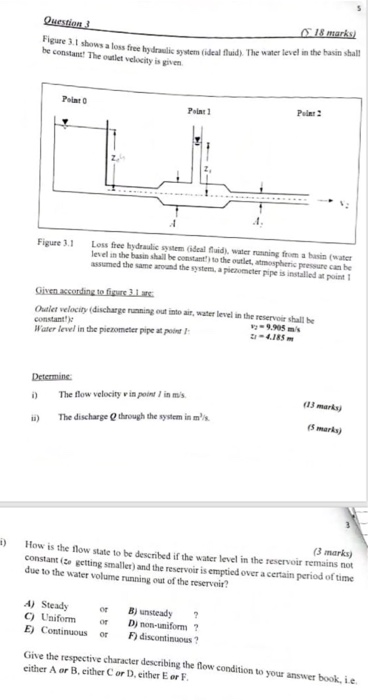

As you can see from the pictures the water was essentially removed after about 160 hours of flushing the head space and was only slightly better in. Once the oil has absorbed any water you have no other options except to COMPLETELY flush the entire system with clean oil. If its just vanilla shake slime on the metal then I would think its condensation and Im not sure how to get that out.

What he stated is an absolute true fact. Taking the time to verify that the system is fully flushed and purged of the old fluid prior to introducing the new fluid will go a long way toward ensuring a healthier hydraulic system. Zoller said that because water generally has a higher specific gravity than hydraulic fluid exceptions do exist eg.

This will also help you determine if theres water mixed in. After 160 hours of head space flush. A simple but effective way to dry the oil is pass a small quantity 4 SCFM of desiccant dry air -40F dew point through the reservoir continuouslyThis technique is often referred to as head space flush.

Drain out the water from the bottom. We would then pump this into another barrel and run the recylcler filter system on this for a. I recently audited a hydraulic system with cloudy oil that was found to contain greater than 1 10000 ppm water.

But there are definitely some different types of additives that you can put in your oil in order to help get that residue which is the best way to put it out Prevention is the best way to keep water out of the hydraulic system. Hans your tractor has no hydrostat componetsThe flush with deisel will work for youJust fill the resevoirs to the proper level with deisel and operate the machine for a few minuteslong enough for it to warm upOperate the hydraulic controls and even move it around in the lower gears if you wantThenjust drain it out and refill with fresh oilYou will be amazed at what the deisel fuel flushes.

But there are definitely some different types of additives that you can put in your oil in order to help get that residue which is the best way to put it out Prevention is the best way to keep water out of the hydraulic system.

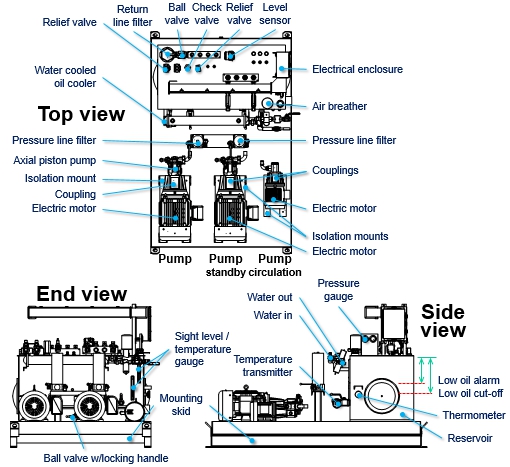

This is similar to case 2 above but the problem here is that there is no accurate way to determine the size and concentration of the contaminant plume at the time when flushing is to start. A simple but effective way to dry the oil is pass a small quantity 4 SCFM of desiccant dry air -40F dew point through the reservoir continuouslyThis technique is often referred to as head space flush. Flush the system with a lower viscosity oil. In such cases draining and adding fresh hydraulic fluid as needed should be fine. A flush should not be necessary for a machine that has been regularly maintained and has not experienced any major failures or contamination. The lower grade oils do not give the same protection as the Kubota oil but it does leave the tractor useable for five to ten hour periods to be able to better purge the whole system of the water. Clean out the reservoir and remove all deposits and sludge. This is similar to case 2 above but the problem here is that there is no accurate way to determine the size and concentration of the contaminant plume at the time when flushing is to start. It only takes a small amount of water to contaminate the system.

Drain the hot flushing oil from the system. By changing the standard element with a water-removing element you can slowly trap the free water as the machine is running. If youve worked with hydraulic equipment for any length of time its likely that youve come across a hydraulic system with cloudy oil. A hydraulic flush purges the system of sludge contaminants including water air and particulate matter and degraded fluid. Ideally this will be done when the fluid is at operating temperature. This method is particularly useful when dealing with pressure sensitive systems. After 260 hours of head space flush.

Post a Comment for "How To Flush Water Out Of Hydraulic System"